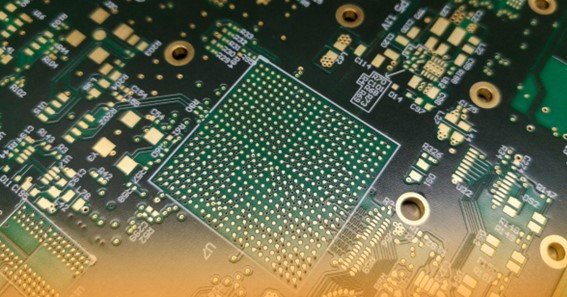

If you look at the latest commercial electronic equipment, you’ll find them filled with several minute devices. Even your iPhone, microwave, and personal computer has them on their circuit boards. As opposed to using standard components, PCB makers mount these components onto the boards’ surfaces using specialized machines. Of importance to note is that most of them are relatively small when it comes to size. The technology used to mount these devices goes by the name Surface Mount Technology (SMT). So, what is SMT in detail and its advantages? This article highlights more about SMT technology. Read more…

What is SMT technology?

Surface Mount Technology (SMT) is a standard procedure in electronic circuit assembly today. Many PCB makers lately rely on SMT technology to manufacture their boards.

Surface Mount Technology is the process of mounting electronic components to the surfaces of PCBs. It is different from Plated Through-Hole Technology and is the best replacement or option for PTH.

With Surface Mount Technology, it’s easy to build even the most complex electronic circuit boards.

By using this technology, you can achieve smaller assemblies with excellent repeatability.

All this is due to the high levels of automation and precision that come with Surface Mount Technology technology.

Many makers now use this technology, which enables them to design small, lightweight, and compact PCBs quickly. Better yet, it’s a much faster process compared to through-hole technology.

Surface Mount Technology doesn’t call for too much work during the assembly.

SMT is a simple process of picking and placing PCB components on the board.

SMT IC Package Types

There are a lot of surface-mount technology packages out there that help with mounting circuit chips. You can look at a few of the more common ones for your PCB:

- Ball Grid Array (BGA): This type has tiny balls soldered on the chip’s bottom surface, which makes it denser.

- Quad Flat Package (QFP): A QFP is a rectangle or square with leads reaching outward from each side.

- Small Outline Package (SOP): SOP is small-sized, so it doesn’t take up much space on a circuit board and has better mechanical stability.

- Quad Flat Non-leaded package (QFN): QFN doesn’t use any leads and has small metal pads to attach an IC on the board.

- Small Outline J-lead package (SOJ): These packages have leads that look like a ‘J’ and come from two sides opposite each other.

- Lead Grid Array (LGA): The lead grid array connects to the PCB via metal pads.

Advantages of SMT technology

Several advantages come with SMT technology that you need to know. If you are considering using SMT technology in your PCB assembly, then you are bound to enjoy some of its benefits. Some of its merits include the following:

Reduced manufacturing costs

Surface-mount technology promises reduced manufacturing costs. SMT allows for the creation of small PCB designs, reducing manufacturing costs.

By using SMT, components can be placed close to each other on the board. Therefore, SMT technology manufacturers enjoy the advantage of highly reduced manufacturing costs.

Improve work efficiency

SMT technology is also one of the best circuit assembly technologies as it improves work efficiency. This is another reason why many PCB makers lately seem to prefer it.

Relying on SMT, tasks can be completed in a single workday and within the shortest time possible. Unlike PTH technology, which may take some time, this is not the case for SMT.

If you choose to assemble using Surface Mount Technology, work efficiency is a significant assurance that you’ll get.

The overall structure is more straightforward.

The overall structure of the boards you manufacture under SMT is simple. Unlike PTH-assembled panels, the design of SMT-made boards tends to be very simple.

Surface-mount technology assembled boards don’t demand too many technicalities, such as drilling. Compared to panels manufactured using other means, those made under SMT have more superficial structures.

Less error-prone

There’s nothing more demanding than having to do circuit board re-works due to errors. Another advantage of SMT technology is that it’s less prone to errors. Unlike detailed PTH, Surface Mount Technology isn’t into too much detail as such.

It’s possible to correct small mistakes on boards made under SMT. Manufacturers prefer this method because it allows them to produce many boards without many errors.

Adaptable to smaller components/high component density

It’s possible to place components on both sites of the circuit board using SMT quite easily. Better yet, you can do all this in higher density.

Another advantage of SMT is the ability to identify parts close to each other. Using SMT, you can quickly achieve more connections per area and more features per unit area.

Higher connection density

SMT technology comes with the promise of higher connection density. Boards made using SMT technology can deliver a message of specific sizes within a particular time.

Surface Mount Technology technology allows the delivery of notices, even in constrained locations.

Need to drill fewer holes.

SMT technology is cheap. You won’t have to drill many holes in your circuit board here, and it doesn’t require many spots to carry signals to other parts of the board.

Mounting holes that you can find on SMT-assembled PCBs are few. With this technology, there’s no need to drill many holes.

Low radiation emission

Perhaps, one of the most significant advantages that come with SMT technology is low radiation emission.

When assembling parts using SMT, you’ll encounter low radiation emissions.

Therefore, it means that SMT is slightly a safer assembly method compared to other assembly methods.

Electromagnetic compatibility (EMC) performance is better than the old technology assembly method.

With SMT, achieving a compact package coupled with lower lead induction is possible. Here, you get the assurance of a small radiation loop area, meaning excellent EMC compatibility. Again, this is another merit that applies if you use SMT technology.

Application of SMT technology

This technology encapsulates more electronic components into smaller spaces on a PCB.

SMT is a technology that will continue to grow in years to come as it is not ending anytime soon.

If you are a printed circuit board assembler, the best way to go is to use this technology. Even though it may cost you more, SMT is one of the best technologies.

The future development trend of SMT technology

Summary

SMT technology has several advantages. It is cost-effective and time-consuming to manufacture. With SMT, you can utilize both sides of the board for placing your electrical components.

The lesser cost of setup and manufacturing is another advantage of SMT technology.

Do you have an upcoming SMT PCB project? Call us today to learn more about PCBs.